3form // Architectural Hardware

3form makes translucent plastic panels for architectural applications. Some are colored and others have stuff cast inside them, like fabric or grass.

When we started collaborating with 3form, we wanted to figure out what architects wanted to do with 3form’s panels. So we interviewed architects in San Francisco and Los Angeles to understand their vision for 3form’s materials. Based on those insights, we developed a series of hardware, lighting and space division solutions. We’ll look at three of them here.

FRAME/

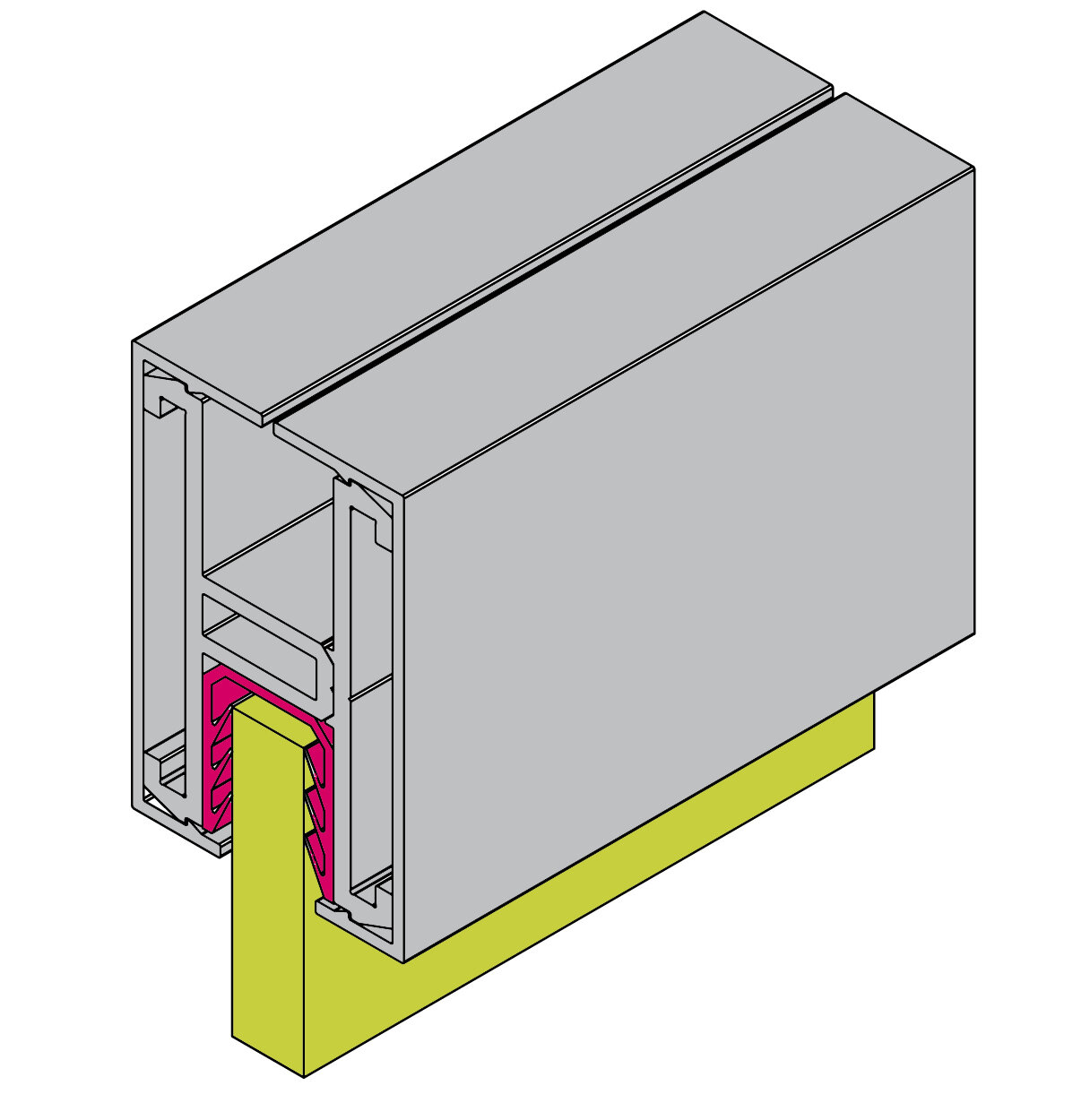

We developed Frame to overcome two problems with existing aluminum glazing systems. The first was aesthetic. Systems designed for glass tend to be a bit clunky, with cluttered lines and thick black gaskets. And the second was practical. 3form panels vary quite a bit from their nominal thickness, unlike glass. So installers were improvising, not always with the best results.

Thing Tank designed a proprietary crush-rib glazing gasket that not only accommodates the variation in actual thickness of 3form products, but renders the glazing invisible by putting it completely inside the channel. No more black lines around the panels. They appear to float in the fame. And we managed to eliminate all visible fasteners and seams from the system.

SLIDE/

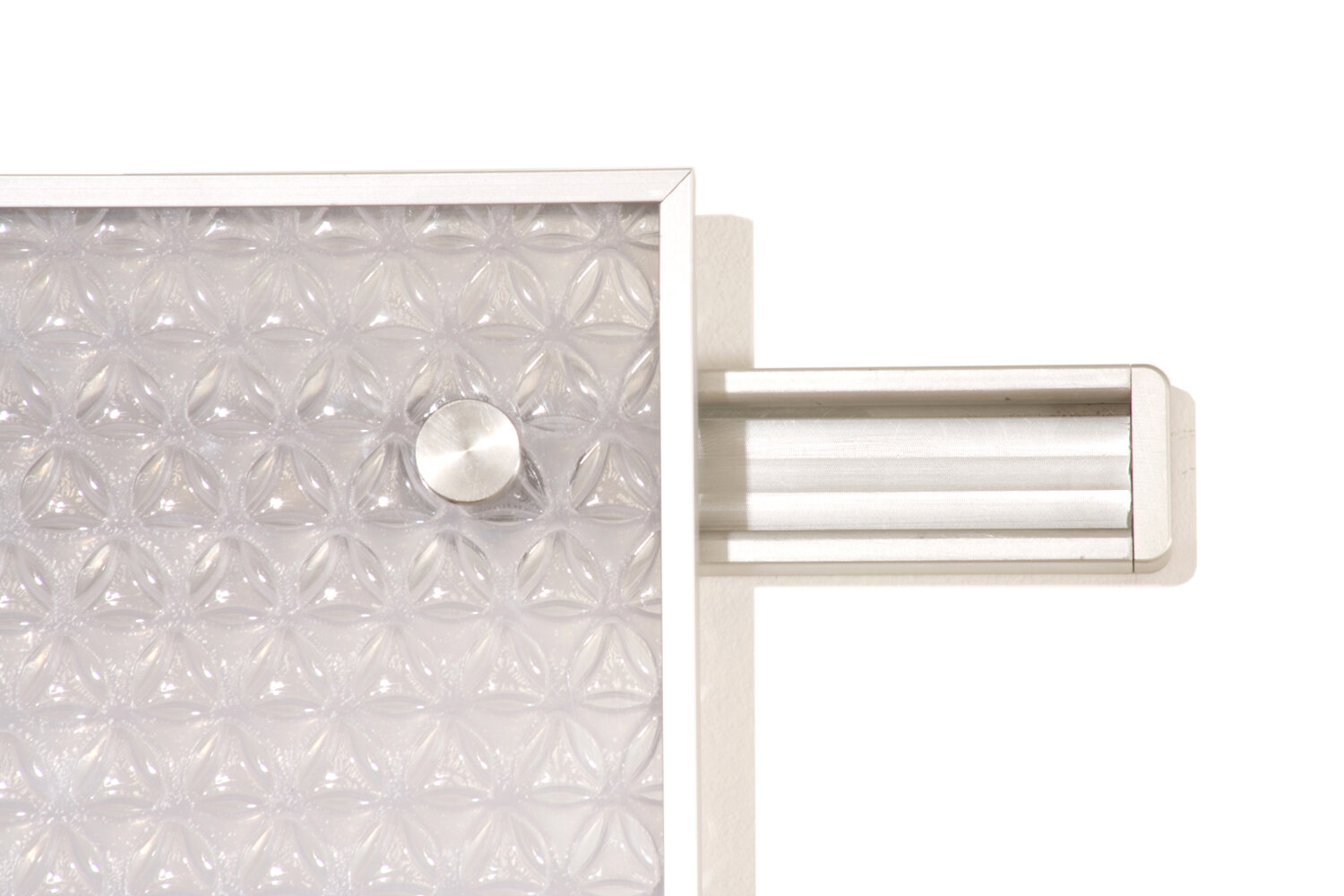

Architects told us that they wanted to use 3form panels to express a floating, frameless, translucent plane. It’s a natural extension of the materiality of the panels themselves. We also found a lot of architects were looking for a clean, minimalist sliding-door solution. Slide is essentially a resin panel, mounted on two standoffs with rollers on them.

With that extreme simplicity come a number of design challenges. Installation always involves some final adjustment. But the minimalist aesthetic of Slide leaves no place to hide the hardware typically used to adjust sliding doors. So Thing Tank designed a unique, patented, eccentric adjustment mechanism into both the standoff roller and the floor roller. The result is a starkly minimal, extremely smooth sliding door system.

TILE CURTAIN/

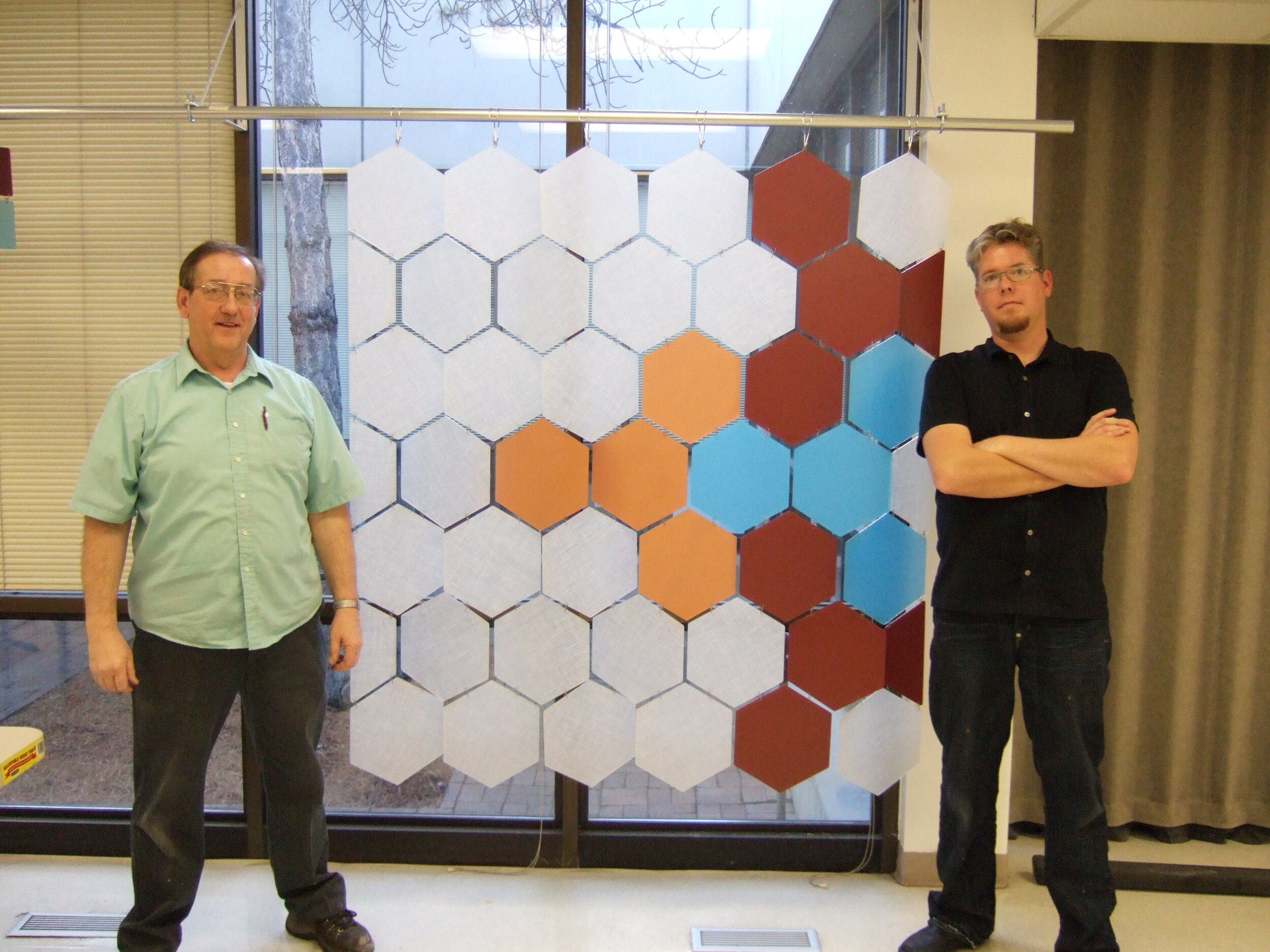

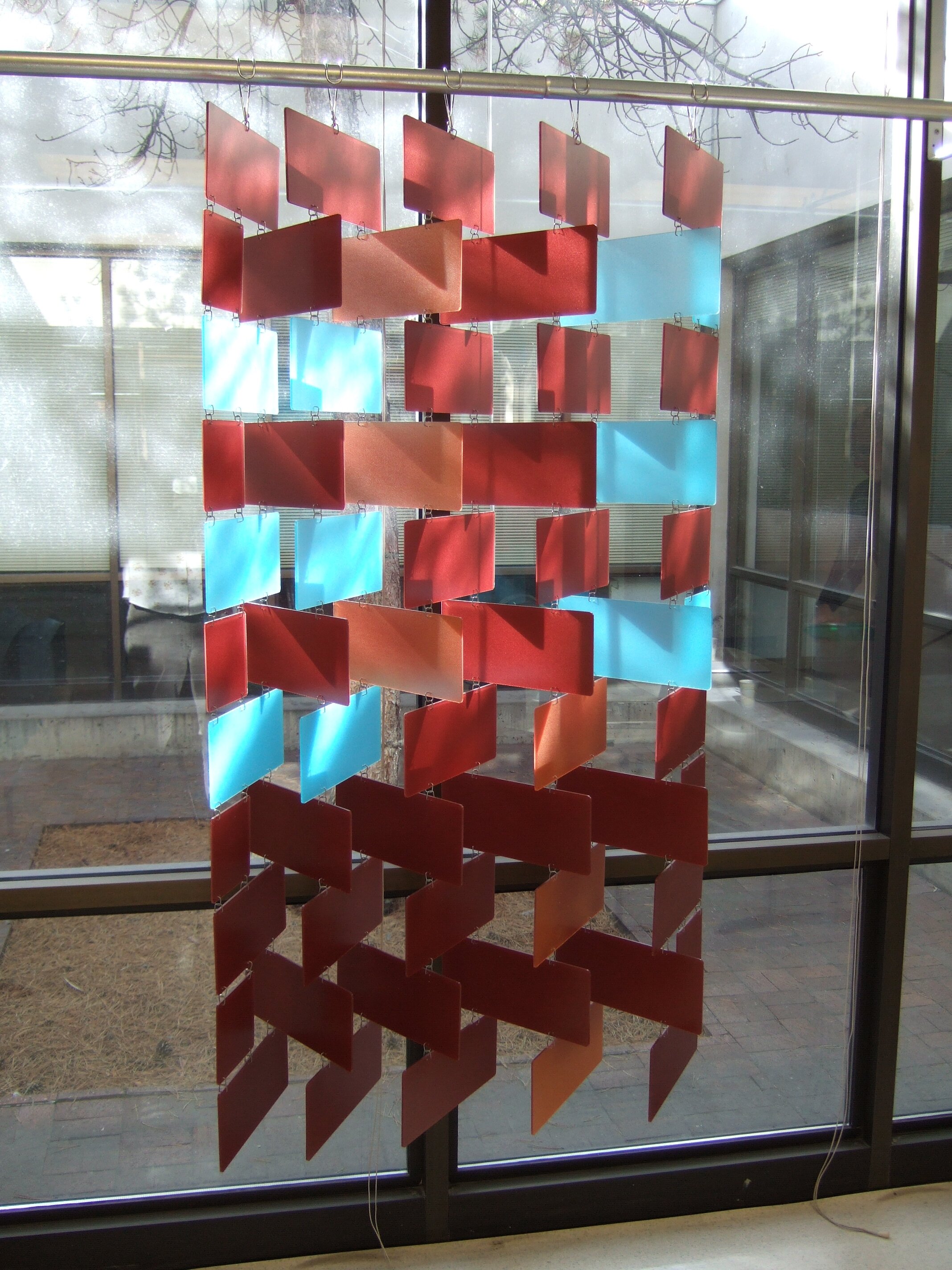

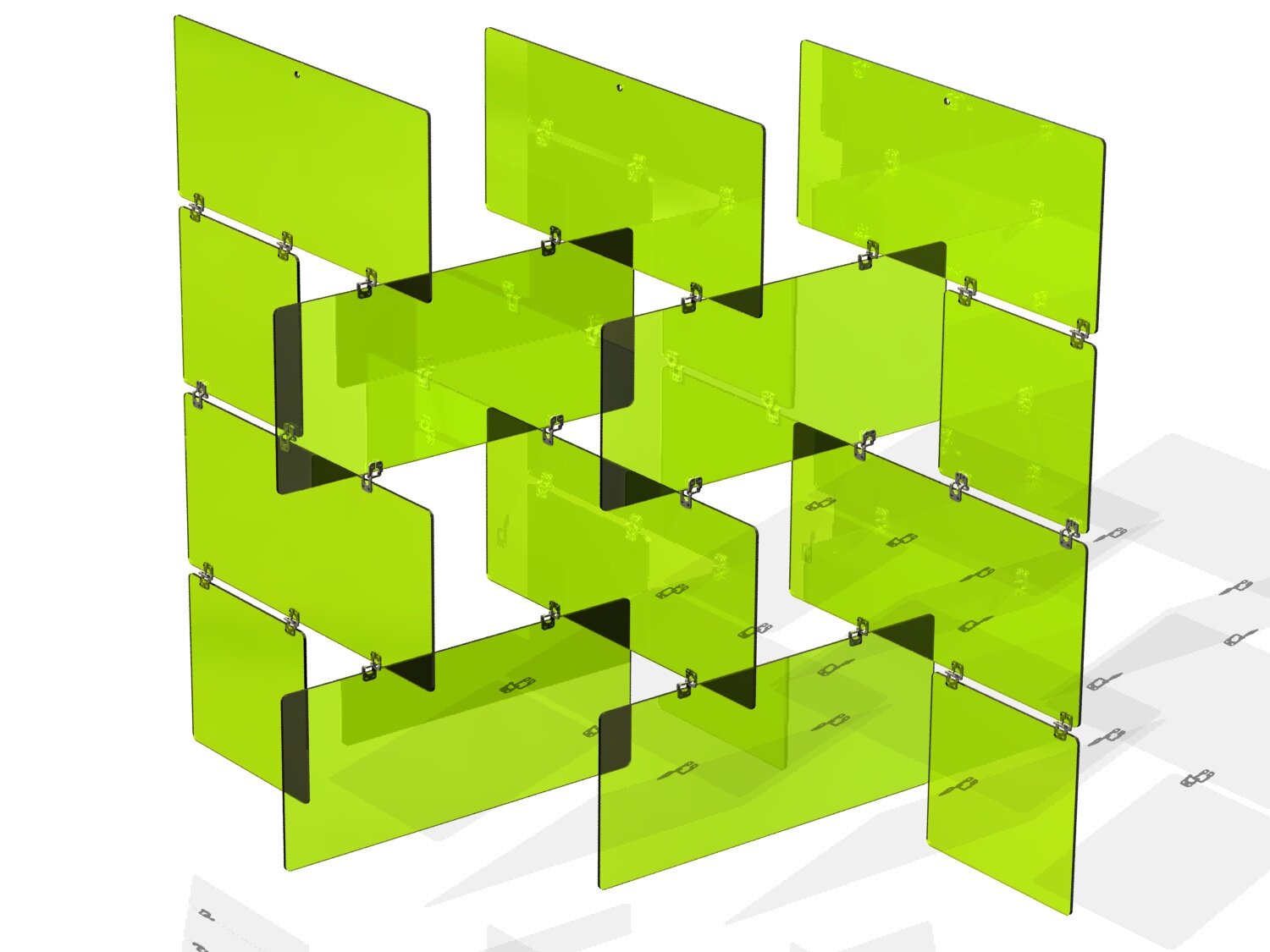

Architects and their clients were asking for frameless, floating applications, like Slide. But to get the required strength to forgo the frame, the panels got thicker, heavier and more expensive. In turn, the hardware to hold them up got chunkier and more expensive. We wondered if we could turn that trend on its head. Instead of a heavier, thicker, stiffer and more expensive direction, could we make the parts lighter, thinner, more yielding and cheaper.

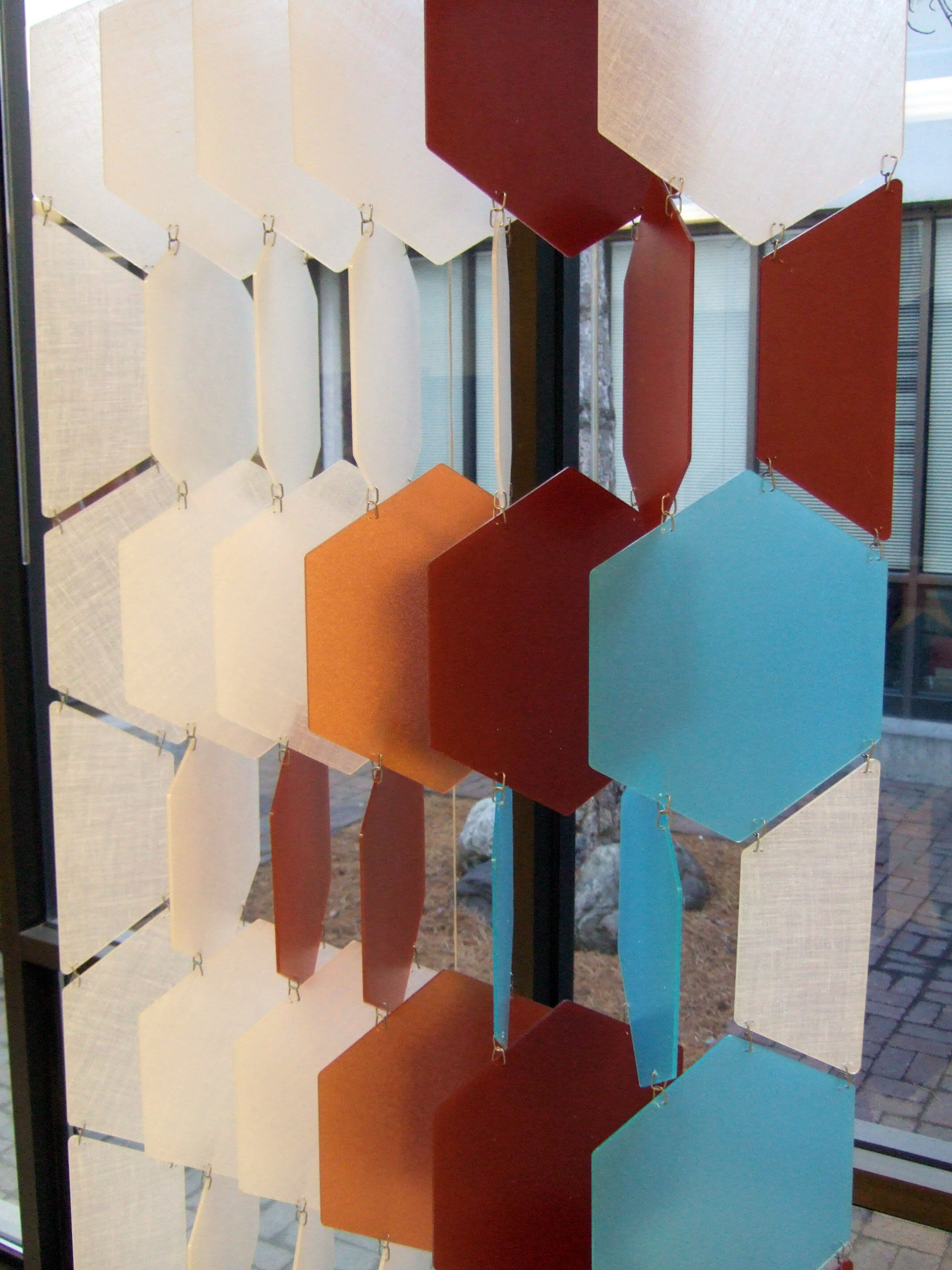

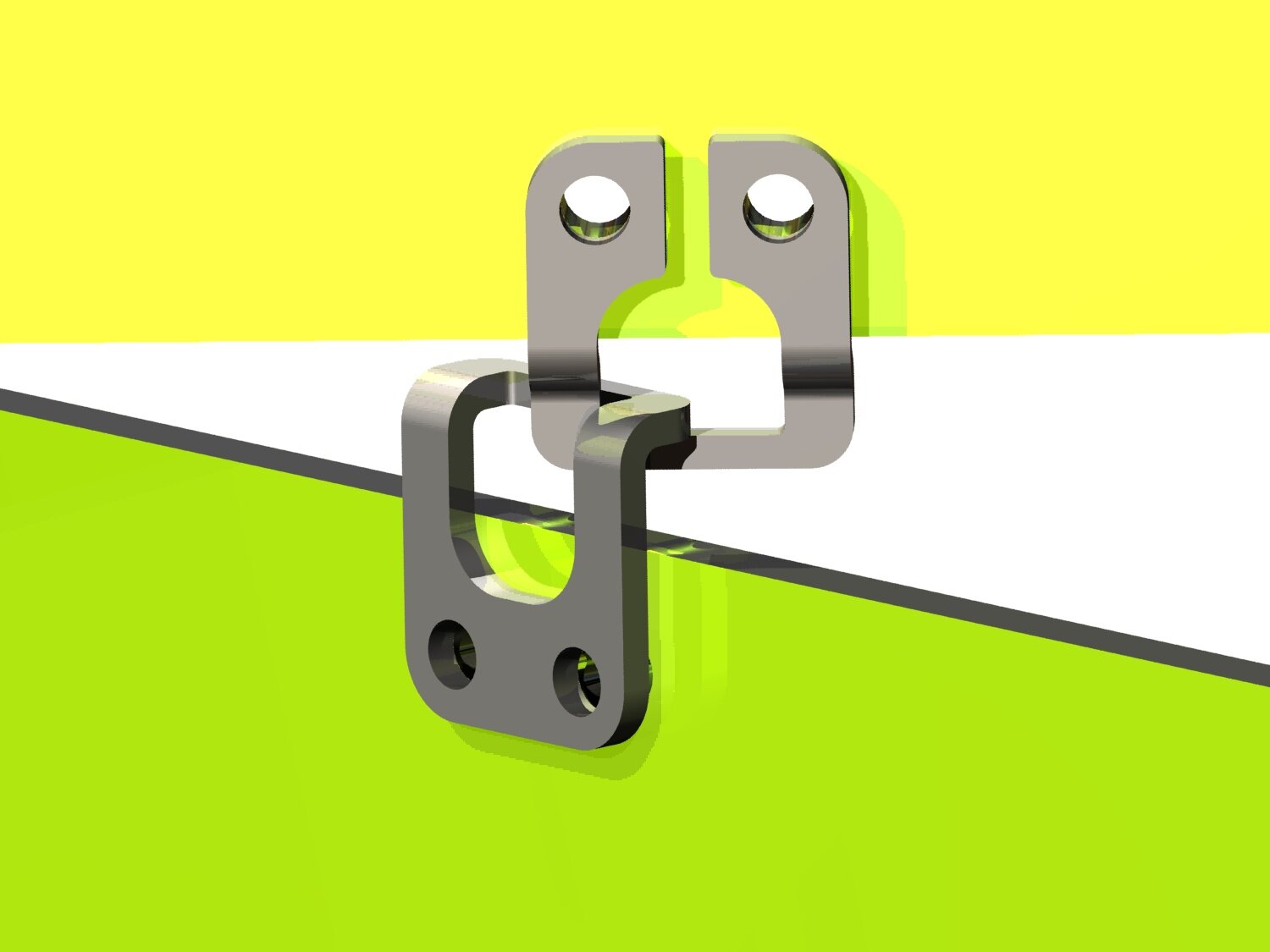

Tile Curtain is just what it sounds like; an array of small, thin 3form panels. The magic part is a proprietary connector system that allows the whole array to fold in a simple, organized fashion. It is totally modular, so it can be as wide as a window or a wall. It can be a light translucent space division, window treatment or wall decoration. It can be a single material, or a mosaic of color.

These prototypes with wire connectors proved the concept, but it was fiddly to assemble. So I developed a bent sheetmetal connector that solved the connection issues, and kept the folds in the curtain more tidy.